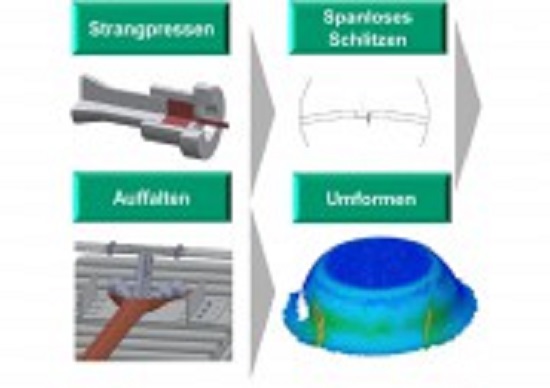

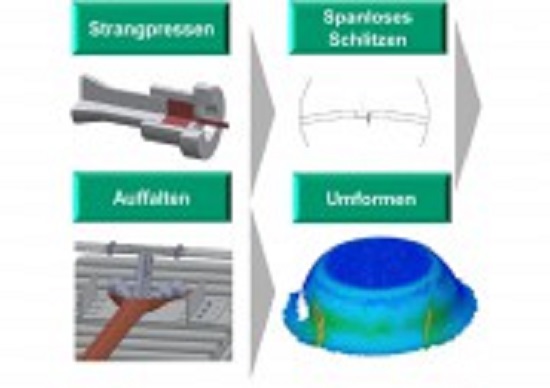

The extrusion and subsequent unfolding of magnesium tubes enables the flexible production of magnesium sheets. However, the forming properties of these sheets differ from conventionally produced sheets. In particular, the influence of the longitudinal press seams on the forming must be taken into account in the process design.

Schematic representation of the process route for the production and processing of magnesium sheets. Image: IFUM / IW, Hannover

Magnesium is one of the lightest construction materials in mechanical engineering. With a density of ρ = 1.7 g / cm³, magnesium only reaches a fraction of the weight of steel or aluminum. In view of the shortage of fossil energy resources and increasing environmental regulations, the need for lightweight construction is increasing, especially in the automotive and aviation industries. While the casting-technical processing of magnesium alloys is already established [1], the production and processing of magnesium sheets is still a niche industry despite the high lightweight potential. The reason for this is to be found in particular in the comparatively difficult shaping-technical processing of magnesium. At room temperature, magnesium and its alloys have a brittle forming behavior. Only with an increase in temperature are pyramidal slip planes of the first order activated and the material can be formed [2]. The need for tempered forming makes it difficult to use magnesium sheets in two ways. A temperature control of the forming process (deep drawing and ironing) increases the processing costs, while the process reliability is reduced by an additional process parameter. Furthermore, the production of semi-finished sheet metal is difficult, since the rolling process for sheet metal production must be tempered. The sheet cools between the rolling stages and must be reheated for the next stage. As a result, the production of sheets is very energy-intensive. Furthermore, this method is limited to the production of fewer alloys or larger lots, since the slabs must be cast separately from the starting material.

As part of this research project, a process was developed in which magnesium tubes are extruded and then transformed from the extruded heat to sheet metal. In this way, a cheap and flexible method for the production of magnesium sheets could be developed. The initial production of pipes on the one hand allows more uniform material properties over the sheet width than when pressing flat semi-finished products and the extension of limited by the press jaw sheet width.

Prof. Dr.-Ing. Bernd-Arno Behrens, Dr.-Ing. Sven Hübner, André Neumanna),

Prof. Dr.-Ing. Hans-Jürgen Maier, Dr.-Ing. Christian Klose, Norbert Grittner, Marcus Engelhardtb)

a) Leibniz Universität Hannover, Institute for Forming Technology and Forming Machines

b) Leibniz University Hannover, Institute of Materials Science

neumann@ifum.uni-hannover.de

At the University 2, 30823 Hannover, Germany

Keywords: magnesium, sheet metal production, extrusion, press seams

From: https://www.umformtechnik.net