Media Spotlight on CIIF|OFweek Laser: What Signals Did the First Day of CIIF Send to the Laser Industry?

On September 23, 2025, the 25th China International Industrial Fair (CIIF 2025) opened at the Shanghai National Exhibition and Convention Center. Spanning an exhibition area of 300,000 square meters, CIIF attracted 3,000 exhibitors from 30 countries and regions globally. Leading laser companies such as Han's Laser, Hymson Laser, and Chuangxin Laser actively participated, with many unveiling new products. On the first day of the fair, OFweek Laser's editorial team was on the front lines, witnessing the surging momentum of "Intelligent Manufacturing in China." What were the highlights of this exhibition? Below, OFweek Laser presents the grandeur of the event.

Han's Laser

At this CIIF, Han's Laser made a grand debut with three new products from the "Blue Crystal" series: A55, A65, and A85. Under the brand proposition of "Making Welding Simpler," the company aims to redefine the performance benchmarks and user experience of handheld laser welding. Among them, the "Blue Crystal" A55 model features a main unit weighing only 45kg and a welding gun weighing a mere 490g. It boasts a wide operating temperature range of -20°C to 45°C, making it adaptable to extreme temperature environments. The "Blue Crystal" A65 model achieves efficient penetration depth with outstanding performance and enables automatic cutting based on graphics, achieving a material utilization rate as high as 98.7%. The "Blue Crystal" A85 model is specifically designed for heavy industrial scenarios such as shipbuilding, heavy machinery, and energy equipment. It is equipped with a triple-wire feeding system and a hybrid liquid-cooled high-power output module, ensuring stable operation in harsh environments like low-temperature cold storage, high-temperature workshops, high-humidity shipyards, and dusty workshops.

Hymson Laser

Hymson Laser showcased its high-speed laser cutting machines, high-speed coil cutting production lines, large-format high-speed laser cutting machines, and high-speed laser tube cutting machines at this CIIF. Among them, the HF-3216G series high-speed machine is the earliest and best-selling domestically pioneered high-speed machine. The latest-generation 3216G high-speed machine exhibited on-site, paired with a fully automatic loading and unloading system, achieves seamless integration of the entire "cutting-unloading-reloading" process.

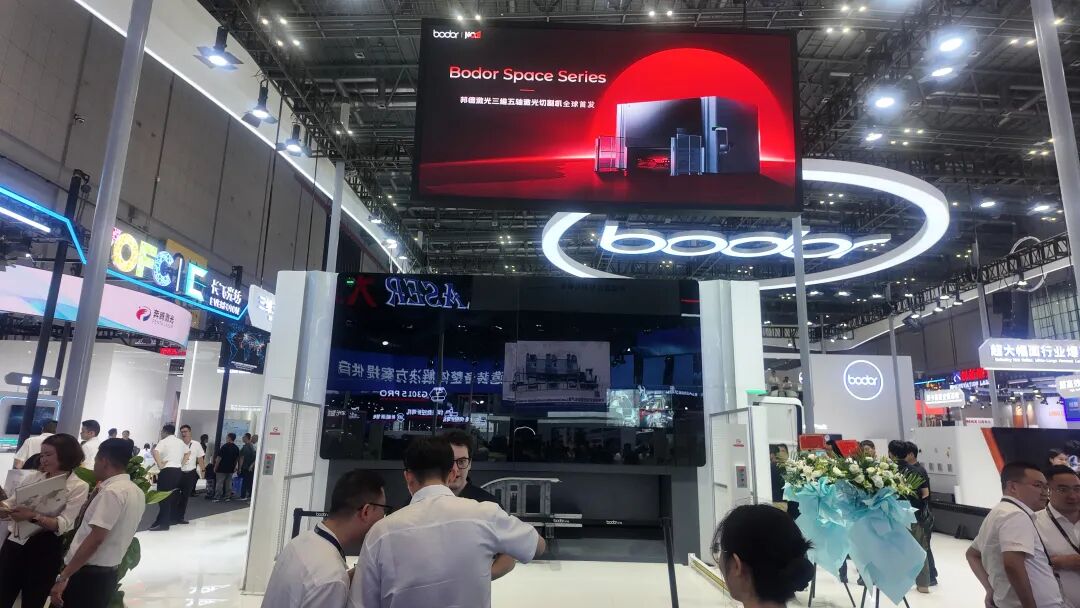

Bodor Laser

Bodor Laser launched its new 3D five-axis laser cutting machine at this CIIF, targeting manufacturing pain points with breakthrough performance. Additionally, Bodor Laser presented several star products, including the L-series laser sheet cutting machines suitable for all scenarios, the S-series laser tube cutting machines capable of cutting ultra-short end scraps as short as 40mm, laser scanning cutting technology that overcomes challenges in processing highly reflective materials, and self-cooling handheld laser welders supporting 24-hour continuous operation. This comprehensive display showcased Bodor Laser's complete ecosystem, from self-developed core components to full-industry-chain solutions.

Quick Laser

Quick Laser introduced the new-generation GI3015 ultra-high-speed laser cutting machine at this CIIF. Redefining new standards for sheet processing with six core advantages—extreme cutting speed, stable base, industry-leading core components, intelligent safety protection, smart and environmentally friendly experience, and highly intelligent operation—it is applicable to thick plate processing industries such as steel structures, shipbuilding, engineering machinery, and sheet metal fabrication.

Furthermore, Quick Laser unveiled the new-generation L1 Ultra high-speed laser tube cutting machine, ready to take on high-standard orders. The new-generation K2 PLUS triple-chuck medium-duty laser tube cutting machine adopts an industry-first triple-chuck structure, helping enterprises reduce costs and increase efficiency.

Max Photonics

At this CIIF, Max Photonics showcased products from its Glory series and XinGuang series. The Glory series utilizes proprietary "Hair Growth Paste" technology (referring to a specific coolant or process aid) and a "Laser Wire" optical path design, along with the industry's first full-trajectory raised nozzle gliding cutting technique, pioneering a new secondary cutting process route for the industry. The XinGuang series, building upon the Glory series, incorporates advanced configurations such as digital spot control, digital system control, path control, and spot-path coordination. It addresses challenges in various fields through disruptive process technologies and beam control capabilities.

YOFC

YOFC presented high-quality, intelligent, and differentiated laser application solutions at this exhibition. In the area of beam core adjustable architecture, YOFC showcased 4,000–15,000W beam-adjustable continuous lasers and 300–1,000W highly stable continuous fiber lasers. For sheet metal processing, it displayed 6,000W single-module continuous fiber lasers, 12,000W single-module continuous fiber lasers, and 30,000W multi-module high-power continuous fiber lasers. For high-precision applications, it featured 800–1,500W air-cooled continuous fiber lasers (new generation), 3,000W QCW air-cooled quasi-continuous fiber lasers, and 3,000W continuous fiber lasers (new generation).

Binzel

Binzel showcased a range of cutting-edge equipment at this CIIF, including the TCU Contact Tip Changer, WH PNE Automatic Neck Changer System, TCP Calibrator, TCS Nozzle Cleaning Station, ABICOOLER 2000 Chiller, EWR2 Gas Saver, ABIHYBRID™ Laser-Arc Hybrid Welding system, MPH Contact-Type Laser Wire-Filling Welding System, MFS-V3.1 Wire Feeding System, 3D Weld Inspection system JOSY, and 4D In-Process Weld Inspection System.

Coherent

Coherent launched the EDGE FL™ series of high-power fiber lasers specifically designed for cutting applications in the machine tool industry at this CIIF. These lasers offer advantages such as high power and flexibility, exceptional beam quality, and high energy efficiency. Beyond cutting heads, the EDGE FL series can seamlessly integrate with Coherent's extensive portfolio of fibers, coupling devices, and process control optics to provide complete laser cutting solutions.

Trumpf

At CIIF 2025, Trumpf released the new-generation Intelligent Flexible Laser Welding Workstation. Featuring a flexible and high-performance intelligent laser welding system focused on precision sheet metal, it newly incorporates BrightLine Scan bright surface welding technology, enabling a combination of deep penetration, heat conduction, and optional wire feeding processes. Dynamic demonstrations were held for equipment including the Trumpf fully automatic 7000 Series Panel Bending Center, Trumpf turnkey 5000 Series Intelligent Laser Welding Workstation, Trumpf innovative 5000 Series Punching Laser Combination Machine, and Trumpf versatile 5000 Series Bending Machine.

BWT

BWT presented the Lightning Plus Fiber Laser at this CIIF, breaking through the three major bottlenecks in thin-sheet processing: efficiency, precision, and cost. The product utilizes fourth-generation pumping source technology, achieving a high electro-optical conversion efficiency of 35%–40%. Its sub-second piercing technology increases production efficiency by 30–50%. Featuring a multi-layer high-reflection structural design, it effectively eliminates back-reflection interference. It is applicable in various fields such as cutting, welding, cladding, cleaning, and precision processing.

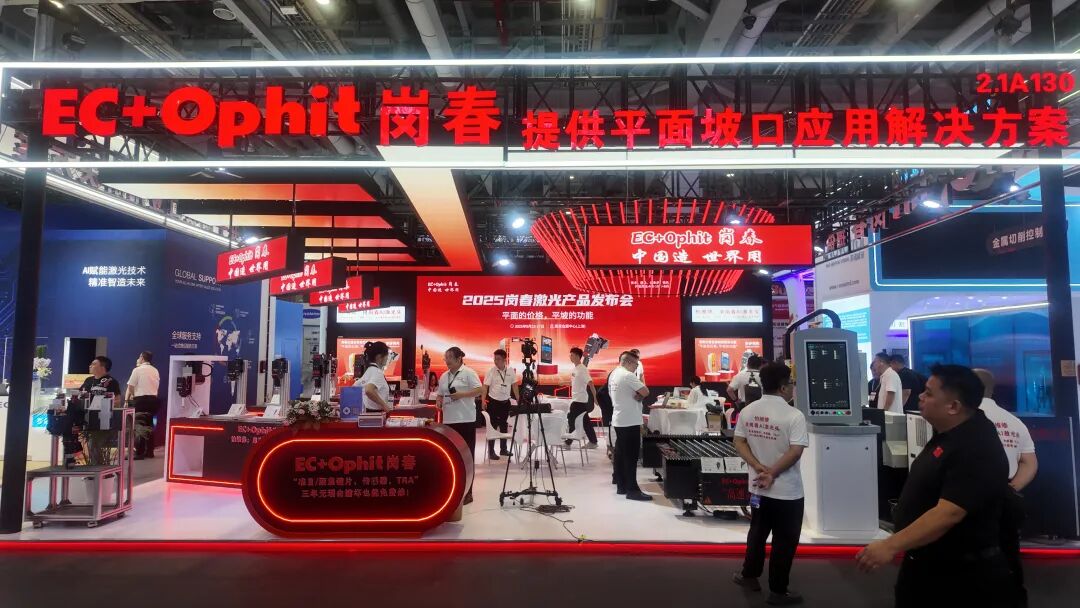

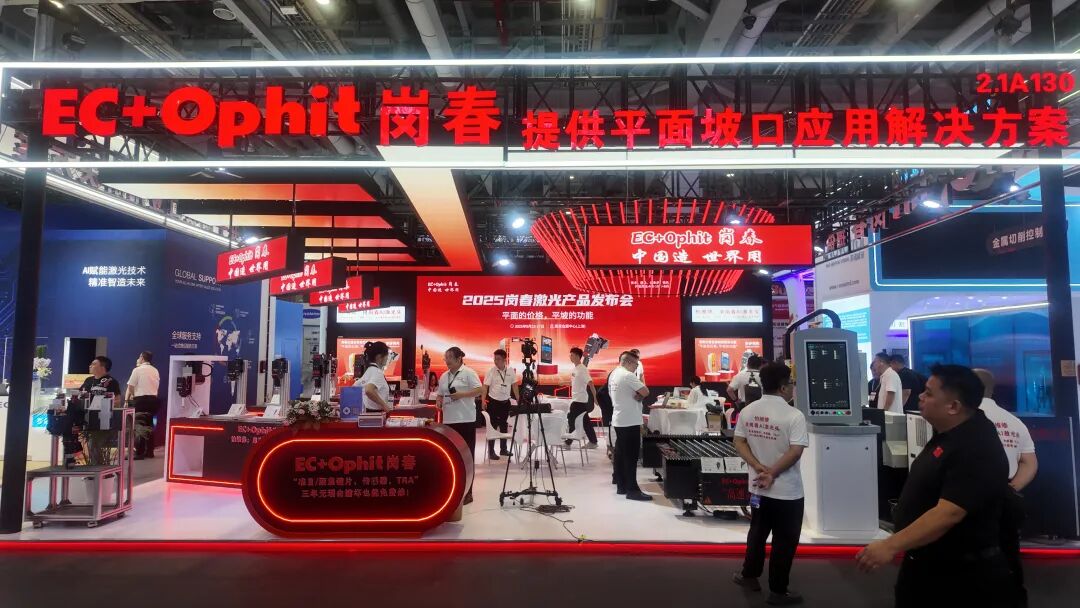

EC (Gangchun) Laser

At this CIIF, EC Laser launched a 60 kW 3D Five-Axis Flat Beveling Solution. The system integrates a 60 kW AI intelligent laser head, a dual-cantilever AB-axis high-speed swing system ("Lightning System"), and embedded nesting software, enabling efficient processing of various metal materials such as copper, aluminum, stainless steel, aluminum alloy, and carbon steel. Additionally, EC Laser previewed the second-generation "Thor" series new product and a new handheld laser cladding product to be released in the next two days. Stay tuned for more highlights.

Source: OFweek Laser