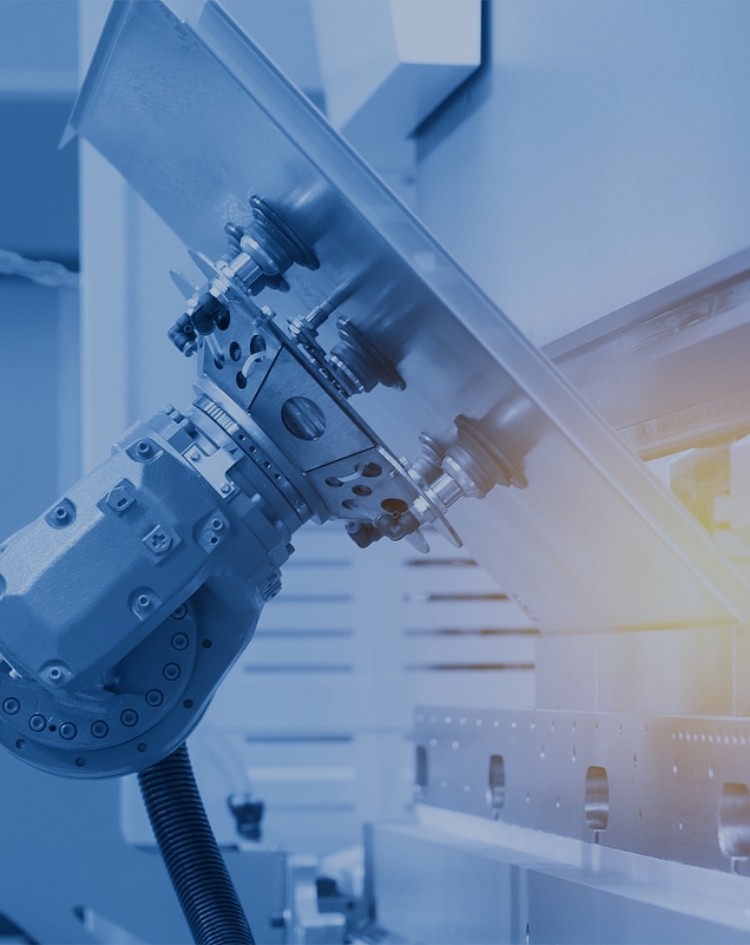

At this fair, Bystronic exhibited a typical sheet metal processing automatic line, which mainly includes material storage, laser cutting machine, automatic loading and unloading and robot bending unit.

Dr. You Song, President of Bystronic China, gave us a detailed explanation of the workflow of this sheet metal processing automatic line, including the loading of materials: the operators use the driving or forklift to transport the raw materials to the stacker, the stacker transports the sheets into the warehouse; the raw materials are taken out: the electric raw material table takes out the whole package from the stock according to the production demand; the loading: the truss manipulator moves to the laser loading area to suck the sheets, and then The sheet is sent to the laser cutting machine exchange table, the Z axis is moved to a safe position, and the laser cutting machine starts to work; the unloading: after the sheet cutting is completed, the truss manipulator is moved to the top of the table, and the gearing tool carries the finished sheet material To the electric trolley; sorting and transshipment: after manually removing the waste, the electric trolley transports the cutting piece placed in the sorting code to the loading area of the bending unit; automatic bending: the robot grabs the cutting piece from the electric trolley, according to The set program is automatically bent, and the pallet is placed on the blanking tray after completion.

Dr. You Song said that this production line can be widely used in aviation, shipbuilding, rail transit, automobiles, chassis cabinets, medical equipment and other fields, which can effectively optimize material flow and information flow, increase equipment utilization rate and improve process reliability.

The automation and intelligent development trend of sheet metal processing technology will definitely promote the transformation of sheet metal processing enterprises, and it is imperative to establish an information processing system. At present, most sheet metal processing companies have introduced information management systems such as ERP and PAL. Intelligent manufacturing equipment is a general term for manufacturing equipment with sensing, analysis, reasoning, decision-making and control functions. It is the integration and integration of advanced manufacturing technology, information technology, computer technology and intelligent technology in equipment products, reflecting the intelligentization of manufacturing industry. , digital and network development requirements. “Bystronic hopes to develop our products along the Smart Factory, that is, not only to sell machines, but also to promote the overall networked solution including software and automation systems. We can no longer consider some In a specific segment, Bystronic will use a global and holistic approach to thinking, focusing on customer needs and helping customers become the World Class Manufacturing in the highly competitive sheet metal industry,” said Dr. You Song.