Penta Laser: Pioneering High-Strength Steel Processing – Penta Laser’s 3D Cutting Technology Showcased, Empowering Intelligent Lightweight Automotive Manufacturing!

On December 5th, the "2025 Geely Automotive Metal Forming Industry Chain Innovation Development Forum," hosted by the Geely Automotive Stamping Association, was successfully held at Geely Automobile's Yuyao Plant in Zhejiang. Centered around the theme "Geely Chain Collaboration, Intelligent Manufacturing for the Future," the forum brought together technical, procurement, and manufacturing leaders from various Geely plants along with core suppliers to explore cutting-edge technologies and collaborative innovation in the field of metal forming.

As an invited premium supplier, Penta Laser’s spokesperson, Mr. Li Yinhua, delivered a keynote technical presentation titled "Applications of Penta Laser's 3D Cutting Machines in the High-Strength Steel Body Lightweight Industry." The presentation highlighted Penta Laser's leading technology and application achievements in 3D laser cutting for high-strength steel and aluminum alloy automotive body components.

01

Specialized Insights: Addressing Pain Points in Lightweight Manufacturing

In the presentation, Penta Laser pointed out that with the rapid development of the new energy vehicle industry and the deepening trend toward vehicle lightweighting, the use of high-strength steel (1500-2000 MPa) hot-formed components in critical automotive safety structures is becoming increasingly widespread. However, traditional stamping and trimming molds face significant challenges when processing these high-strength materials, including high mold costs, long lead times, slow iteration, and insufficient flexibility. These limitations make it difficult to adapt to the market demand for rapid model updates and multi-variant production.

Driven by the pursuit of higher efficiency and greater flexibility, 3D five-axis laser cutting technology has emerged as a key enabler, offering broad application potential to address these industry challenges.

Against this backdrop, the need for more flexible and efficient processing methods has become a pressing industry requirement. This has created favorable conditions for the widespread adoption of 3D five-axis laser cutting technology and laid the groundwork for subsequent technical solutions.

02

Technology Application: Laser Empowering the 'Steel Skeleton'

Penta Laser further elaborated in the report that with the widespread application of ultra-high-strength steel hot-formed components (with strengths up to 2000 MPa), traditional stamping processes face immense challenges. Penta Laser’s 3D five-axis laser cutting technology, with its advantages of "no molds required, non-contact processing, high precision, and high flexibility," is becoming a critical process solution to address these industry pain points.

01 Processing Hot-Formed Components: An Industry-Standard Process

With minimal heat-affected zones and no workpiece deformation, 3D laser cutting serves as an excellent replacement for traditional trimming and punching molds. It significantly enhances the efficiency of new vehicle prototype development and has become the preferred process for leading automotive manufacturers in processing hot-formed components.

02 Integrated Door Ring Cutting: Enabling Structural Weight Reduction by 20%

For integrated door rings with strengths as high as

1500 MPa, Penta Laser offers specialized 3D cutting solutions that achieve higher cutting precision and edge quality while meeting the demands of complex contour processing. This approach has garnered significant attention from mainstream automakers.

03 Battery Trays and New Material Components

In application scenarios involving new materials such as new energy vehicle chassis, battery trays, and aluminum alloy frames, 3D laser cutting also demonstrates its advantages in high flexibility and consistency.

04 Cross-Industry Adaptability

Beyond automotive manufacturing, Penta Laser’s 3D five-axis technology has also matured in fields such as

mold manufacturing, engineering machinery, and the processing of various other complex three-dimensional curved components, showcasing strong potential for cross-industry expansion.

03

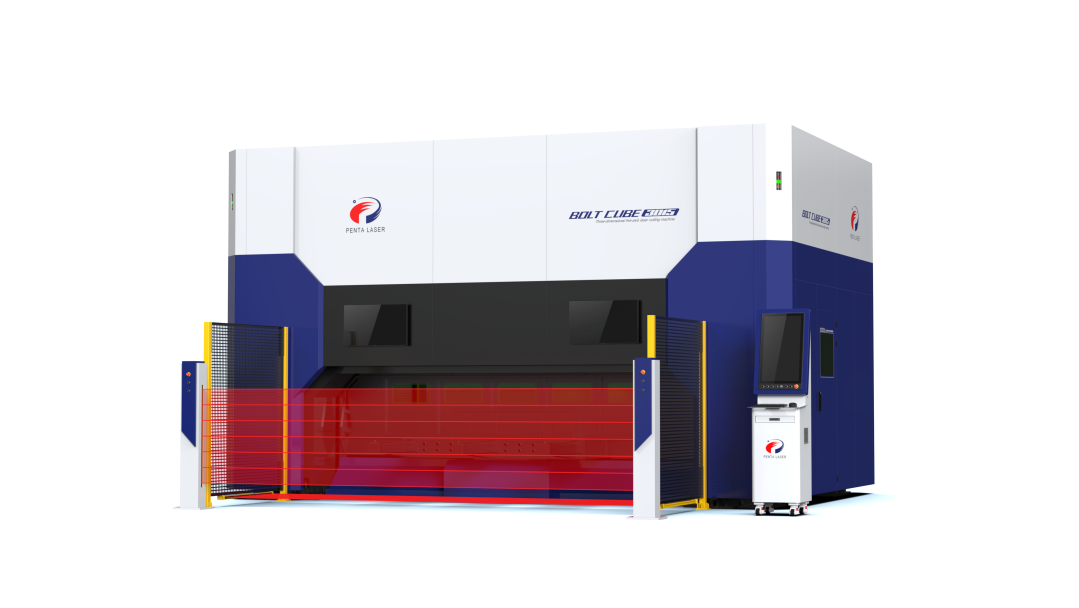

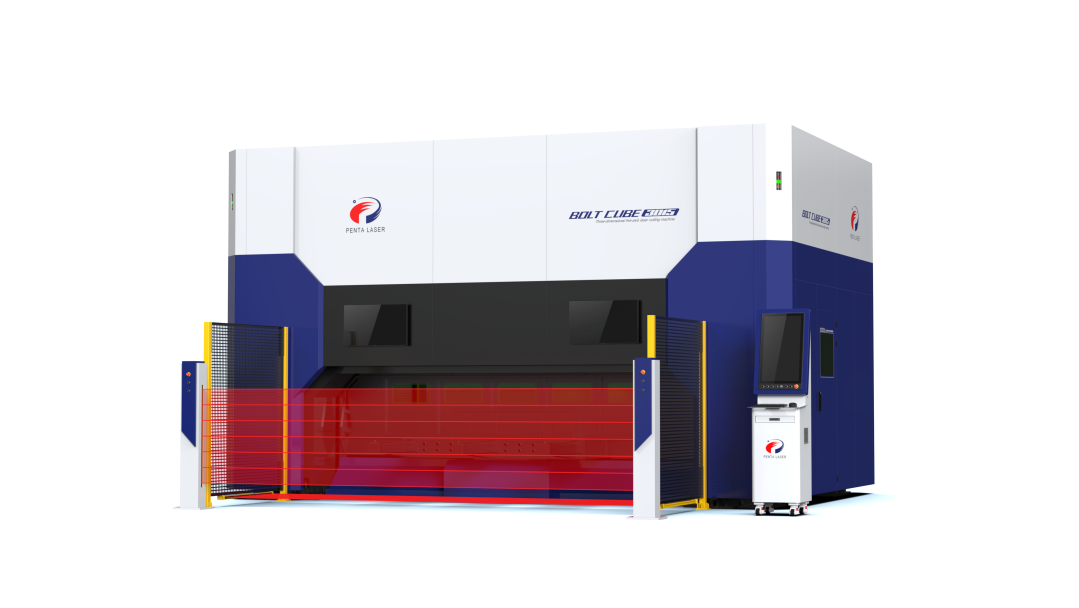

High-Performance Equipment: BOLT CUBE Series Products

To meet the stringent requirements of automotive hot-formed component processing, Penta Laser leverages its deep expertise in equipment manufacturing and industry application experience to independently develop and launch the BOLT CUBE series of 3D five-axis laser cutting machines. This equipment specializes in cutting holes and trimming edges of components, offering exceptional processing quality, long-term stable operation, and excellent return on investment, making it a reliable and efficient production choice in this field.

01 Integrated Design: Space-Saving, Faster Deployment

The BOLT CUBE 3015 model features fully enclosed protection and a "three-cabinet integrated" structure, with dimensions of only 6.5m × 6.5m × 3.8m (length × width × height). Its ease of maintenance makes it suitable for rapid production line setup and capacity expansion.

02 High-Rigidity Platform + Dual-Station Structure: Balancing Precision and Efficiency

The high-rigidity body ensures stability during high-speed processing. Equipped with a standard dual-station rotary table, the station change time is less than 3 seconds, enabling simultaneous processing and loading/unloading, significantly improving production line efficiency.

03 Intelligent Control System: Simplifying 3D Processing Operations

The machine is equipped with advanced control software (Smart Manager) and professional 3D programming software (Smart 3D Pro). Key features include online program modification, automatic focus control, and RTCP automatic calibration, ensuring smart and user-friendly operation.

04 High-Performance Cutting Head: Effortlessly Handling Complex Surfaces

The machine features an infinitely rotating C-axis 3D cutting head with automatic focus adjustment, anti-collision protection, and new capacitive sensing technology. It can easily achieve high-precision hole cutting and edge trimming on complex spatial surfaces of automotive components.

Through this forum, Penta Laser and the Geely ecosystem have further deepened technical exchanges and cooperation consensus. Moving forward, Penta Laser will continue to focus on innovation and application in 3D laser cutting, high-strength steel lightweight processing, and intelligent production lines. By collaborating with automotive manufacturing partners, Penta Laser aims to build a synergistic, efficient, and green intelligent manufacturing ecosystem. With its advanced laser intelligent manufacturing capabilities, Penta Laser is committed to supporting the Chinese automotive industry in advancing toward a new stage of high-quality development.

Source: Penta Laser