Post-Show Recap|WILA: Jiangsu WILA Press Brake Tooling Systems Co., Ltd. Shines at Shanghai CIIF, Demonstrating Innovative Strength in Bending Processing

As a core professional exhibition of China International Industrial Fair (CIIF) and the premier international event in the sheet metal field, the Shanghai CIIF MWCS (Metalworking & CNC Machine Tool Show) focuses on high-end, intelligent, green, and innovative development directions. It spans an exhibition area of 80,000 square meters, gathers over 600 leading global enterprises, and attracts 200,000 professional visitors. Covering 12 core industries including aerospace and automotive manufacturing, it has become a central platform for industry exchange, cooperation, and new product launches in the sheet metal processing sector.

As the Chinese subsidiary of the Netherlands-based WILA B.V., founded in 1932, Jiangsu WILA Press Brake Tooling Systems Co., Ltd. inherits nearly a century of technical expertise and innovative spirit in press brake tooling and clamping systems. The company is a well-known supplier of press brake tooling systems, automatic (hydraulic/pneumatic) clamping systems, mechanical compensation systems, and efficient bending solutions, possessing globally leading bending technology aimed at helping press brake manufacturers improve production efficiency and optimize bending quality.

At this exhibition, the company presented a range of core technical products and cutting-edge solutions, becoming a focal point in the sheet metal processing field. The booth received over a hundred groups of professional visitors daily during the event. Domestic and international clients engaged in in-depth consultations on core product performance and technical application scenarios, showing high interest in innovations such as "AI + Bending" technology and automatic tool change systems. Multiple groups expressed intent for cooperation on-site, fully demonstrating the company's leading role in industry technological advancement.

01 Hydraulic Clamping System and Bending Tooling System: The Foundation for Efficient Bending

As one of our best-selling classic products, WILA hydraulic clamping systems are compatible with all press brakes and are particularly suitable for "small batch, high variety" sheet metal processing scenarios. With just a single button press, the tool clamping and releasing process is completed, eliminating cumbersome manual locking methods. WILA bending tooling is renowned for five key characteristics: "precision, durability, flexibility, speed, and safety." It supports vertical tool installation, reversible tool mounting, automatic tool seating, and automatic alignment of the bending line, permanently eliminating the need for manual tool alignment. This completely removes the traditional press brake tool alignment and adjustment process, significantly shortens production preparation time, effectively enhances the overall operational efficiency of bending production lines, and provides foundational support for cost reduction and efficiency improvement.

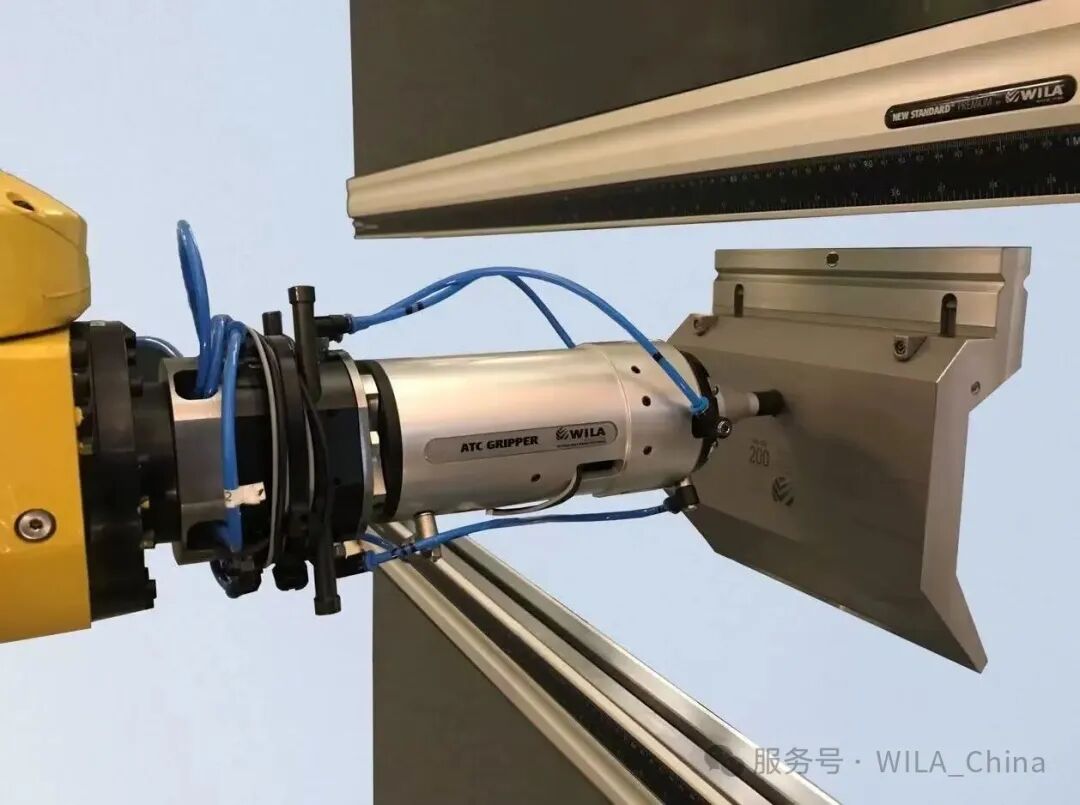

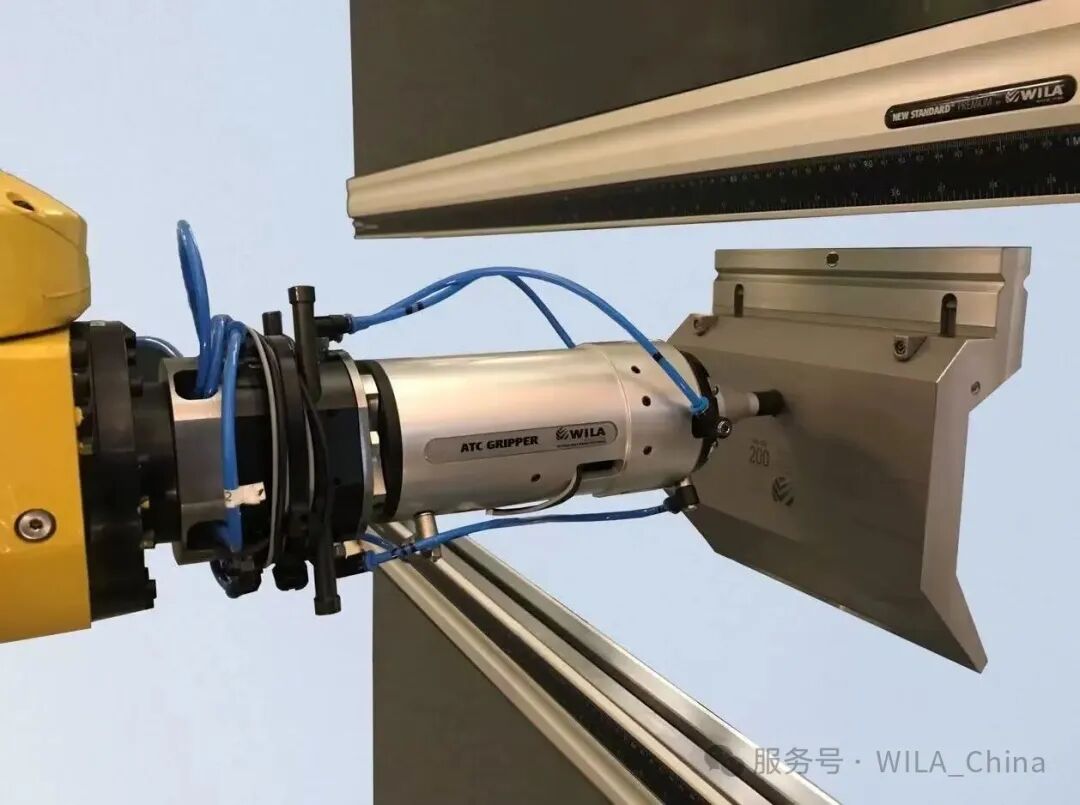

02 Automatic Tool Change (ATC) System: The Core Solution for Fully Automated Production

This exhibition showcased our mature ATC system, a key solution for automated bending of small-batch, high-variety parts. The system innovatively integrates a complete chipset within the clamping unit and embeds chips in the tools, creating a synergistic linkage mechanism between "clamping unit – tool – robot." Once the tool is installed and clamped with a single button, the clamping unit chip automatically identifies the tool chip information, accurately reads critical details such as tool position, model, and parameters, and transmits this data in real-time to the robot and press brake. Building on robot-assisted automatic bending, the robot uses our specialized gripper to perform automatic tool changes without any manual intervention. This not only maximizes fully automated bending operations but also significantly improves bending efficiency and product yield. It helps customers shorten the return on investment (ROI) period and achieve a higher ROI, effectively addressing the inefficiencies and errors of traditional manual tool changes.

03 WILA Pneumatic Clamping Series: A Green and Efficient Adaptable Solution

In response to the trend of industrial greening, we exhibited the classic WILA pneumatic clamping series. Driven by compressed air instead of traditional hydraulic power, this series is particularly suitable for electric press brakes. Its core advantages are significant: firstly, it requires no hydraulic oil or hydraulic power unit, making it cleaner and more environmentally friendly; secondly, it operates on standard workshop compressed air (6–8 bar), eliminating the need for additional high-pressure power sources; thirdly, it features a pneumatic self-locking mechanism to ensure operational safety; fourthly, it offers ultra-fast clamping speed, improving bending and tool change efficiency; fifthly, it has lower long-term operational costs; sixthly, it aligns with sustainable development principles, combining environmental and economic benefits; and seventhly, it offers wide compatibility, allowing flexible installation and use on both new and old press brakes, providing enterprises with a low-cost, highly adaptable green processing option.

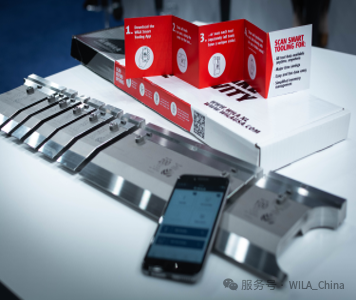

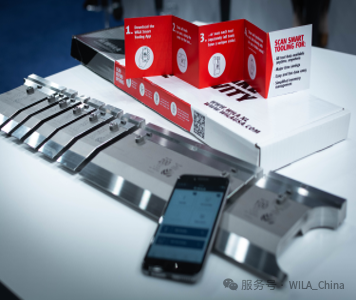

04 WILA Smart Tooling with DM Code: A New Tool for Digital Management

To help enterprises achieve digital tool management, we also exhibited the classic WILA Smart Tooling with DM code. All new standard WILA tools are equipped with a unique DM code, ensuring traceability for each tool set. Using the exclusive WILA Smart Tooling APP, users can scan the DM code on the tool itself or its packaging with a mobile phone or terminal device to quickly access the tool's specifications and performance parameters. These parameters can be shared with enterprise cloud platforms for inventory management or directly uploaded to the press brake controller for automatic parameter calling, eliminating manual data entry. This streamlines processes such as tool storage, inventory checks, and parameter setup, reduces human error, and makes tool management smarter and production preparation more efficient, providing foundational data support for the digital transformation of bending production lines.

05 "AI + Bending" Bend Sense Technology: An Innovative Exploration in Digital Transformation

This exhibition introduced the forward-looking "AI + Bending" technology, marking a new stage in fully automated bending technology. Based on AI algorithm recognition principles, the clamping unit integrates multiple rows of LED lights, a PCB board, and a dedicated chip. By using the built-in LED lights and chip to perceive the QR code embedded in the tool in real time, the Bend Sense system can accurately identify comprehensive information such as tool position, orientation, and model, enabling real-time data collection and analysis. The automatic tool change system based on Bend Sense not only significantly improves operational stability and recognition accuracy but also reduces equipment operating costs. It provides core technical support for building fully automated bending production lines in the bending industry, helping enterprises achieve breakthroughs in both production efficiency and product quality control.

Since its inception, WILA has been deeply committed to the fields of press brake clamping, tooling, and automation. With a focus on technological innovation and lean production, the company collaborates closely with industry partners to drive efficient, green, and digital development in the sheet metal processing industry.

Source: WILA