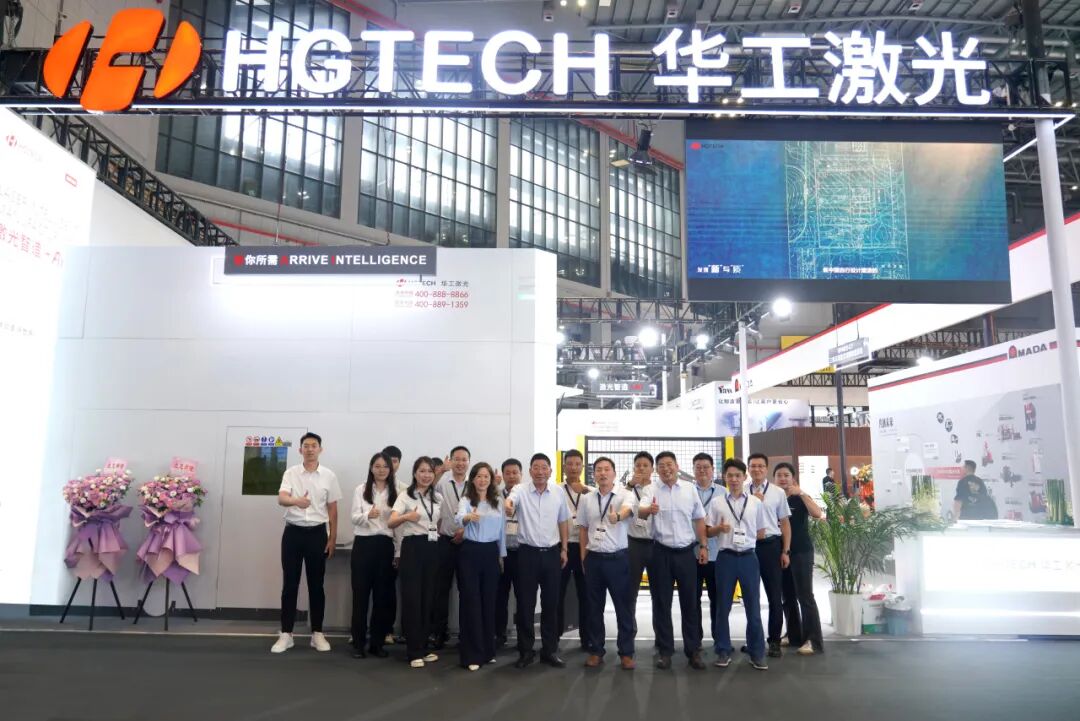

Post-Show Recap | HGTECH: Dual-Model Deployment! Huagong Laser's 3D Five-Axis Laser Equipment Shines at CIIF

The 2025 China International Industrial Fair was grandly held from September 23rd to 27th at the National Exhibition and Convention Center in Shanghai. Huagong Laser showcased two of its latest 3D Five-Axis Laser Cutting Intelligent Equipment units at the exhibition, demonstrating the pinnacle of laser "intelligent" manufacturing in industries such as automotive manufacturing, ship and bridge building, and sheet metal processing.

Centered on 3D five-axis laser cutting technology, Huagong Laser presented the SF4025-CT Laser Cutting Intelligent Equipment and the SF8080-PF Laser Cutting Intelligent Equipment, offering a comprehensive display of the processing capabilities of 3D five-axis technology.

SF4025-CT Laser Cutting Intelligent Equipment

More Efficient 3D Five-Axis Laser Cutting✦

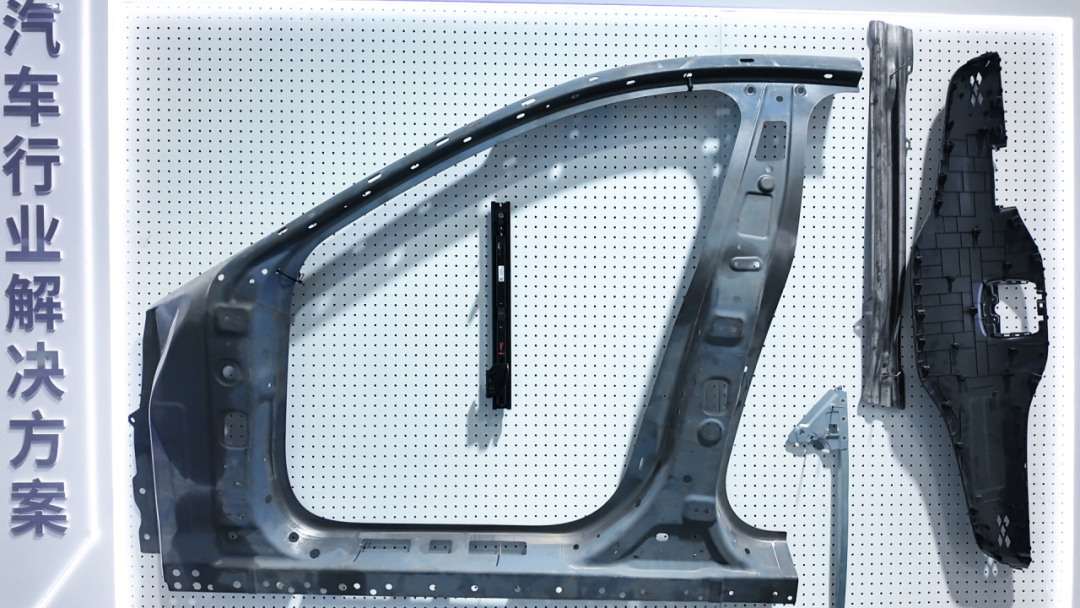

The SF4025-CT 3D Five-Axis Laser Cutting Intelligent Equipment is a laser processing system specially developed and designed for the automotive hot-forming industry. It addresses the needs for hole cutting and trimming of 3D metal hot-formed parts, particularly door rings, delivering high processing quality and stable performance.

Capable of cutting materials such as high-strength steel, plain carbon steel, stainless steel, and aluminum alloy, it is suitable for batch production.

Dual-Head Cutting, Stable and EfficientUtilizing a gantry dual-drive structure and equipped with two sets of high-rigidity, high-dynamic-response beams and Z-axes, it can simultaneously cut workpieces with two cutting heads, significantly improving processing efficiency.

Suitable for Large-Size Part Cutting

The cutting table employs a rotary table method with rapid dual-station exchange, saving processing time more effectively. It is suitable for cutting large-sized parts.

SF8080-PF Laser Cutting Intelligent Equipment

A Flexible System for Small to Medium-Sized Workpiece Cutting ✦

The SF8080-PF 3D Five-Axis Laser Cutting Intelligent Equipment is a flexible system specifically developed for processing small to medium-sized workpieces. It is capable of 2D/3D laser cutting and handles materials including high-strength steel, plain carbon steel, stainless steel, and aluminum alloy.

This equipment offers high precision, a compact footprint, and allows for integrated transportation and easy automation integration. It meets the demands of processing various workpieces with high-precision requirements.

High-Speed, Stable Machine Structure

Utilizing a gantry structure with a high-rigidity, high-dynamic-response beam, it features characteristics such as light weight and excellent dynamic response. Transmission components, including servo motors, guide rails, and high-precision ball screws, employ renowned domestic and international brands. The integrated gantry structure ensures high-speed positioning, rapid dynamic response, and exceptional stability.

Stable Bed, Easy InstallationThe bed is manufactured from an integrally welded structure, undergoes full artificial aging, and can be hoisted as a single unit. It boasts high rigidity, excellent stability, and convenient installation.

Stable Dynamic ProcessingThe equipment features a rationally designed structure that is reliable and stable, with sufficient static, dynamic, and thermal rigidity. The system delivers outstanding dynamic performance.

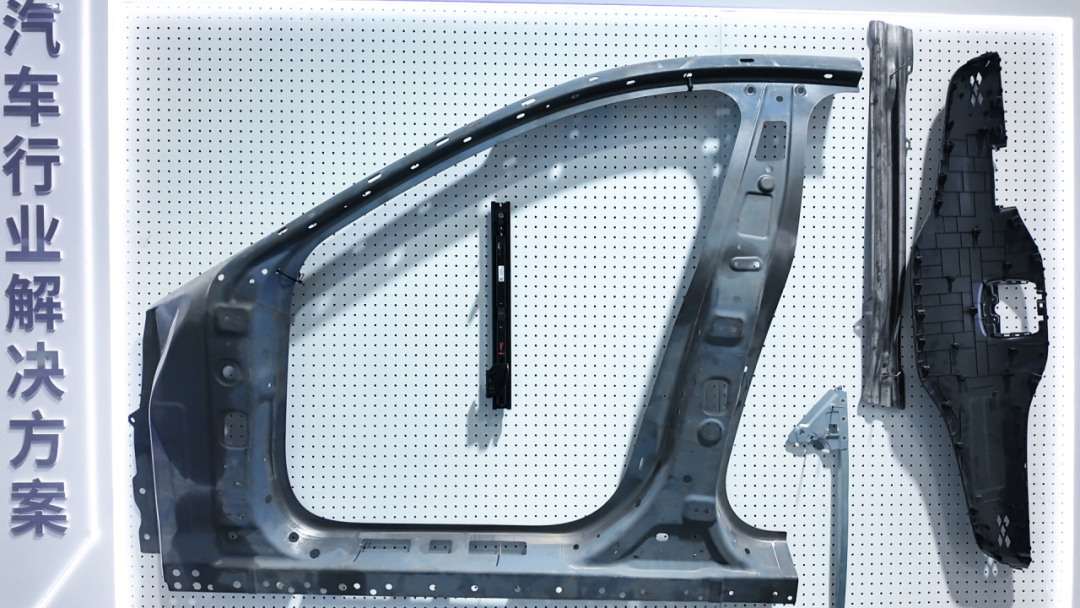

To address automotive industry production needs, Huagong Laser leverages the advantages of 3D five-axis laser cutting to develop a series of intelligent equipment, providing comprehensive solutions for customer requirements.

Multi-Domain Application Showcase

HGTECH also presented a rich array of industry exhibits, with on-site specialists providing detailed explanations of their series of solutions for automotive manufacturing, ship and bridge building, sheet metal processing, and more.

Intelligently Meeting Your Needs

In line with the theme of "Intelligent, Connected, Green" for this year's China International Industrial Fair, Huagong Laser fully showcased its latest achievements in laser intelligent manufacturing combined with AI. The company is continuously enhancing laser processing precision and efficiency, developing solutions that are "world-first, industry-leading, specialized, sophisticated, and innovative" around the production needs of countless industries, creating limitless possibilities for intelligent manufacturing.

Source: HGTECH